PANDORA ETHICS REPORT 2016

10

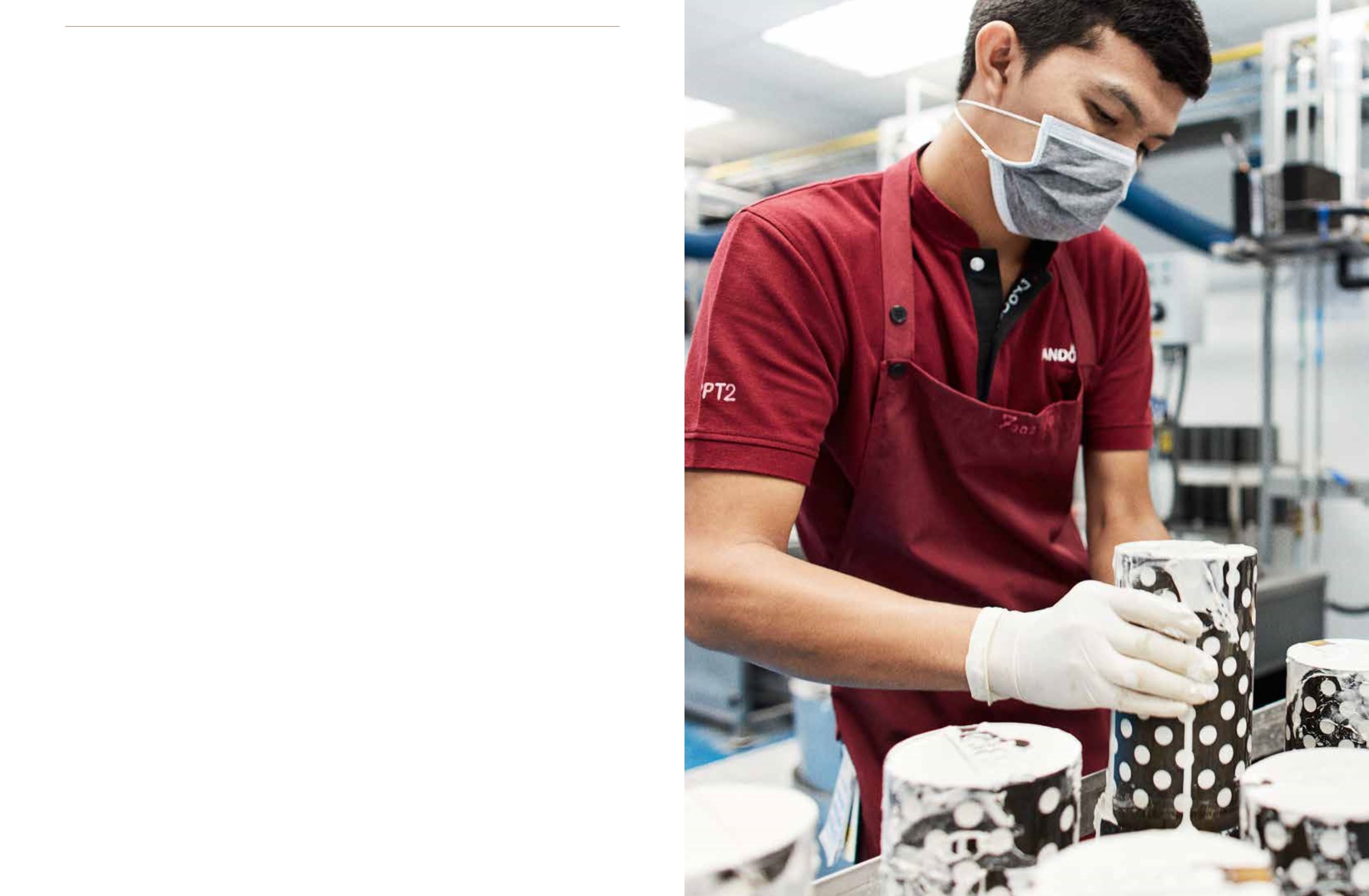

FOCUS ON THAI LAND

Our modern manufacturing facilities in Thailand provide

safe, healthy, developing and engaging working conditions

for more than 12,400 people. Their skills, commitment, flair

for aesthetics, and the way they bring their hearts and minds

to work every day are a major part of the foundation of our

vision to become the world’s most loved jewellery brand.

In 2016 we initiated a Social Impact Study of our engagement

in Thailand. Results are expected in 2017.

Training and development

PANDORA Production Thailand (PPT) has built its success

on the 4C philosophy of Clarity, Competence, Confidence

and Commitment; the four key, interdependent pillars

essential to long-term development.

When our people have clarity in their roles and responsibilities,

the competence to master their craft and think outside the

box and, finally, the confidence and channels to express

their ideas and concerns, the result is the fourth “C”: a deep

commitment to the workplace that manifests itself in PPT’s

status as an employer of choice with a very high employee

retention rate and exceptional performance year after year.

Recognising that access to education is a challenge in

Thailand, we have established an Edutainment Centre, which

features modern e-learning/internet facilities and a library.

This provides our colleagues with a comfortable and inspiring

environment where they can relax and learn. During 2016,

the library in Bangkok had more than 18,000 visits and

more than 5,000 books were available throughout the year;

the most popular genres being adventure fiction and English

proficiency studies. This successful initiative has been

replicated for our new crafting facility in Lamphun.

The scope of our training and development programmes goes

far beyond technical skills and work processes, and includes

life skills, safety, health, environmental practices, business

continuity and leadership. In 2016, we opened a new and

ambitious Jewellery Skills Academy, which drives technical

development through specific skills from beginner to expert

levels. Every week, approximately 50 colleagues receive

dedicated training at the Academy.

Health and safety

At PPT, we operate an effective Safety, Health & Environment

(SHE) Committee comprised of senior management

(16 members) and elected employee representatives

(15 members). The 15 employee representatives are offered

modern, on-site facilities and receive comprehensive training,

both in-house and externally, enabling them to effectively

contribute in their roles. Together with external experts, the

elected representatives assume the responsibility of

checking SHE conditions, while our highly competent SHE

professionals are responsible for continuously improving

standards as well as correcting non-compliances.

SHE professionals are involved in all new production set-ups

to make safety a priority from the start. In 2016, more than

14,000 people participated in training sessions in general

health & safety and firefighting. SHE communication entails

TV and radio spots, engaging events and competitions for

employees to suggest SHE improvements.

As a result of our ongoing focus on improving safety and

health standards, we saw as few as 4 near misses and

2 work-related accidents at PPT (resulting in a total of 8 lost

working days). With 12,400 people employed at PPT by the

year end, this is a remarkably low accident rate compared

with any industrial sector in any country.

Employee Welfare Committee

We have also established an Employee Welfare Committee,

which consists of 15 people elected by their colleagues every

second year. New committee elections were held in 2016,

with a participation rate of 86%. The committee operates

with three sub-committees, responsible for coordinating

employee interest in a) Compensation & Benefits,

b) Employee Relations and c) Social Activities. As is the case

for the SHE Committee, the Employee Welfare Committee

draws on modern facilities and extensive training.

PPT employee benefits include affordable and healthy

meals, parental classes, extensive professional and personal

development training, annual outings, scholarships, employee-

operated radio and TV channels, and free bus transportation

to and from work.

A large amount of gypsum is used in

our jewellery casting process